Hanwha Momentum

Business Areas

Hanwha Momentum is engaged in secondary battery, display,

clean logistics, factory automation, and new and renewable energy

industries based on thermal and automation technologies.

Clean Logistics

Display/semiconductor clean logistics equipment is a clean, automated facility specialized in clean manufacturing processes.

We provide a total solution optimized to meet customer needs, including logistics consulting, design, installation, and after-sales service.

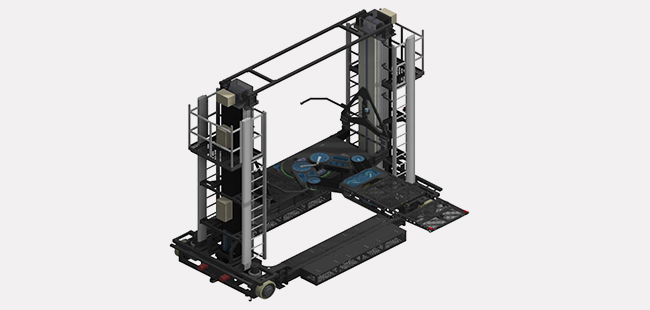

Clean Stocker (Glass Cassette)

It is a display clean automation equipment that store/preserve/transport Glass Cassette and can be implemented according to customer requirements.

Spec

- Environment Cleanness : Class10~Class1000

- Pay Load : Max. 1,000kg

- Velocity : Max. 3.5m/sec

- Velocity : 1.5m/sec

- Acc/Dec : 0.75m/sec²

- Fork Loading Time : within 11

- Vibration : RMS 0.3 G or less

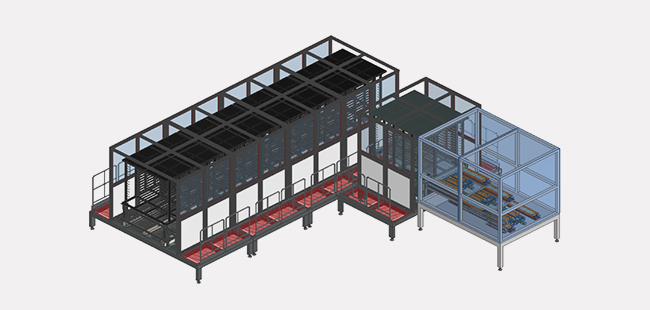

BRC (OCS : Overhead Conveyor System)

It is a display clean automation equipment that transport Glass Cassette between logistics equipment and can be implemented according to customer requirements.

Spec

- Environment Cleanness : Class10~Class1000

- Pay Load : Max. 1,000kg

- Velocity : Max. 2m/sec

- Vibration : RMS 0.8 G or less

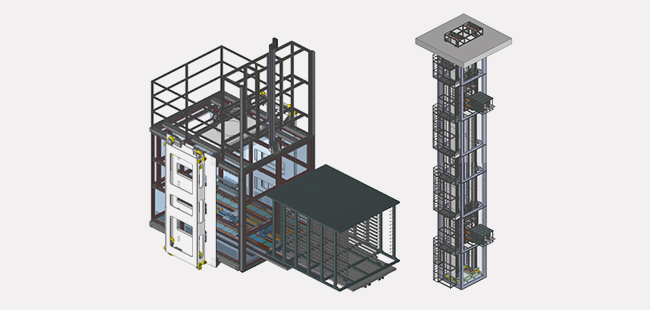

Clean Lifter

It is a display clean automation equipment that transport Glass Cassette between floors and can be implemented according to customer requirements.

Spec

- Environment Cleanness : Class10~Class1000

- Pay Load : Max. 1,000kg

- Velocity : Max. 2.5m/sec

- Height : Max. 90m

OHT

This semiconductor clean automation equipment transfers wafer FOUP, FOSB, POD, and glass FOUP between logistics equipment and process equipment and can be implemented according to customer specifications.

Spec

- Environment Cleanness : Class10~Class1000

- Pay Load : Max. 70kg

- Velocity : Max. 3.5m/sec

- Acc/Dec : 1.5m/sec²

- Vibration : RMS 0.8 G or less

Clean Stocker (Wafer FOUP & FOSB & POD)

This auto storage system is for the clean logistics system for semiconductors, which stores and sorts the wafer FOUP, FOSB, POD, and cassette. It can be implemented in various types of forms such as a chamber type, rack type and others that suit the required specifications of different semiconductor processes.

Spec

- Environment Cleanness : Class1 ~ Class1000

- Velocity : 1.5m/sec

- Acc/Dec : 2.5m/sec²

- Vibration : Not greater than RMS 0.5 G

- Purge : PN2 purge at all times

- Environment Control : Humidity, Temperature, Pressure, oxygen concentration

Tower Lifter

Being the clean logistics system for semiconductors, it is an auto lift & storage system that transfers the wafer FOUP&FOSB to each floor.

Spec

- Lifting Stroke : Max 60m

- Lift Velocity : 360m/min

- Fork Loading Time : Within 3sec

- Acc/Dec : 2m/sec²

- Vibration : Not greater than RMS 0.8G

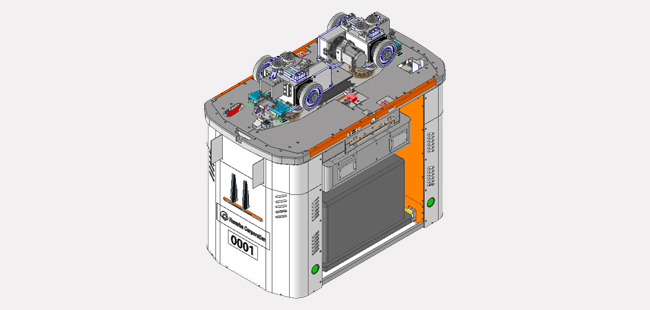

OHT

This semiconductor clean automation equipment transfers wafer FOUP, FOSB, POD, and glass FOUP between logistics equipment and process equipment and can be implemented according to customer specifications.

Spec

- Environment Cleanness : Class10~Class1000

- Pay Load : 10~70kg

- Velocity : Max. 3.5m/sec

- Acc/Dec : 1.5m/sec²

- Vibration: RMS 0.8 G or less

EFEM

This semiconductor clean logistics equipment transfers semiconductor wafers from FOUP & FOSB to process equipment and can be implemented according to customer specifications.

Spec

- Environment Cleanness : Class10~Class1000

- Velocity : 0.7m/sec

- Rotate : 240°/sec

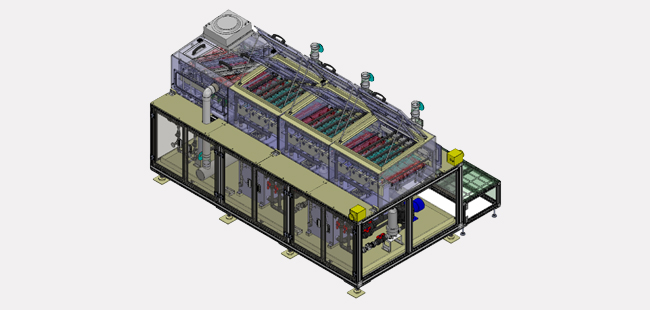

Cleaner

This equipment removes impurities on the substrate during the display/semiconductor manufacturing process and can be implemented according to customer specifications.

Features

- Oxide Blocking

- Cleaning Uniformity

- Temperature Control

- Minimal Use of Utilities

- Safety

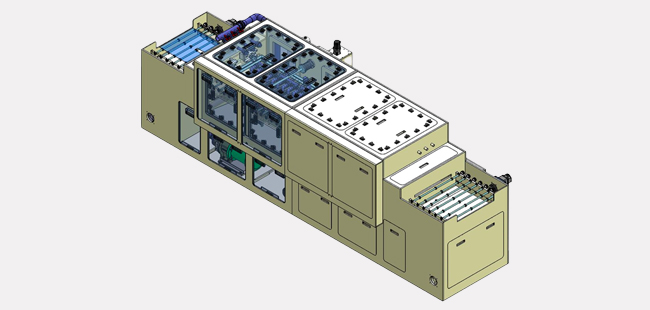

Developer

This equipment develops PR exposed in the display/semiconductor manufacturing process and can be implemented according to customer specifications.

Features

- Develop Fume Blocking

- Develop Uniformity

- Temperature Control

- Minimal Use of Utilities

- Safety

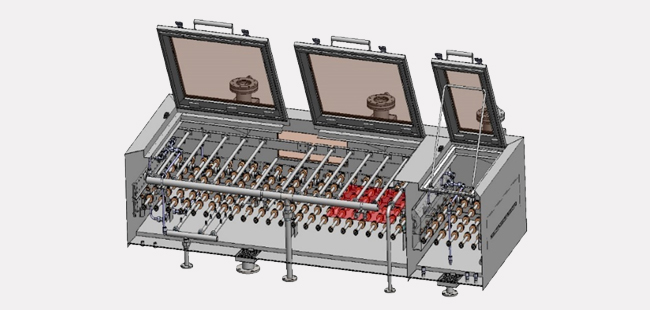

Stripper

manufacturing process and can be implemented according to customer specifications.

Features

- Strip Fume Blocking

- Strip & Remove Uniformity

- Temperature Control

- Minimal Use of Utilities

- Safety

All rights reserved.

All rights reserved.